Pharmaceutical Packaging Equipment Market to Reach $16.24B by 2032 Driven by Pharma Expansion & Automation

U.S. pharmaceutical packaging equipment market grows with pharma expansion, automation, and rising demand for efficient, compliant packaging solutions.

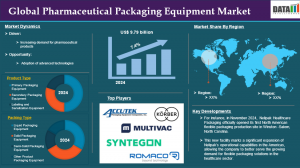

AUSTIN, TX, UNITED STATES, September 29, 2025 /EINPresswire.com/ -- The global pharmaceutical packaging equipment market reached nearly USD 9.79 billion in 2024 and is projected to grow at a CAGR of 7.4%, reaching an estimated USD 16.24 billion by 2032. This expansion is propelled by increasing pharmaceutical production, growing demand for generics and biologics, and the need to meet strict global regulatory and serialization standards. Asia Pacific and North America are the key markets, with Asia Pacific emerging as the fastest-growing region due to expanding manufacturing and investment in new technologies. The market continues to evolve as automation, quality assurance, and sustainability take center stage in packaging machinery development.Download Latest Sample of This Strategic Report (Use Corporate Email ID For Preference) @ https://www.datamintelligence.com/download-sample/pharmaceutical-packaging-equipment-market

Industry Updates, Recent Launches, Investments, and Developments in Pharmaceutical Packaging Equipment

United States (US) Pharmaceutical Packaging Equipment

In August 2025 Syntegon launched its next-generation integrated serialization module for bottle filling lines, helping US manufacturers exceed new FDA and DSCSA requirements for track-and-trace. The solution is projected to improve packaging efficiency by 25% in high-volume facilities and is backed by partnerships with major generics producers.

In July 2025 IMA North America announced a $50 million investment to expand its Philadelphia packaging machinery assembly plant, aiming to double production capacity over three years and enhance service for US biologics manufacturers.

In June 2025 Uhlmann Group partnered with a leading US CDMO to implement automated cartoning and visual inspection systems, slashing end-to-end packaging time by 30%. The collaboration underscores a trend toward “smart” packaging lines in the US pharmaceutical market.

Japan Pharmaceutical Packaging Equipment

In July 2025 Marchesini Japan introduced a high-speed blister packaging solution for sterile injectables in conjunction with Osaka University Hospital. The system targets improved sterility, faster changeovers, and is designed to capture 10% share in the Japanese contract packaging market within two years.

In May 2025 TOWA Pharmaceutical invested in sustainable material-ready blister lines, piloted in Tokyo. The lines enable compliance with Japan’s forthcoming eco-packaging mandates and set the stage for greener supply chains.

Global/Other Regions Pharmaceutical Packaging Equipment

In August 2025 Uhlmann Group signed a strategic supply agreement with India’s largest vaccine manufacturer to provide automated filling and sealing equipment, supporting a regional vaccine output surge. This project is aligned with India’s PLI incentives and expected to accelerate mass immunization readiness.

In July 2025 Optima Pharma rolled out serialization-ready bottle filling systems in Germany, enabling compliance with recent EU Falsified Medicines Directive amendments. The launch reinforces European leadership in traceable, secure packaging for oral and liquid pharmaceuticals.

Market Dynamics

Drivers

• Regulatory compliance and serialization mandates: Rising global regulatory requirements for tamper-evident, child-resistant, and serialized packages are forcing pharmaceutical companies to adopt advanced packaging equipment.

• Growth in generics, biologics, and personalized medicine: The rise in generic drug production and biologics increases the need for flexible, high-speed, and accurate packaging, particularly for injectables and specialty drugs.

• Automation and digitalization: Pharmaceutical manufacturers are investing in automated, integrated packaging lines for greater throughput, quality control, and real-time track-and-trace.

• Expansion of global vaccine and chronic disease markets: Large-scale vaccine campaigns and increased demand for chronic disease therapies necessitate reliable, scalable packaging solutions.

Restraints

• High capital investment and maintenance costs: Sophisticated equipment and integration can require substantial upfront investments, especially challenging for small and medium manufacturers.

• Stringent validation and qualification: Complex machinery and regulatory audits prolong product launches and can slow the pace of change.

Opportunities

• Emerging markets modernization: Asia Pacific and Latin America present strong growth opportunities as governments and private players invest in new pharmaceutical manufacturing facilities.

• Sustainable packaging initiatives: New machinery designed to handle eco-friendly, recyclable, or biodegradable materials is increasingly in demand.

• Integration with digital supply chain platforms: Real-time device monitoring, predictive maintenance, and traceability are adding value.

Challenges

• Balancing speed and customization: As dosage forms diversify, packaging lines must balance large-scale efficiency with flexibility without compromising regulatory compliance.

• Workforce training and technical skills gap: Advanced equipment requires a highly skilled workforce, which can be a challenge for new adopters.

Market Segments

The pharmaceutical packaging equipment market is chiefly segmented by equipment type, dosage form, automation, and end user. Filling machines and blister packaging equipment dominate, making up over 70% of demand, with filling machines leading due to their essential role in injectables and liquids, while blister pack machinery is crucial for securing tablets and capsules. Solid dosage equipment holds the largest share by dosage form, given the popularity of tablets and capsules, followed closely by liquid packaging lines supporting syrups and injectables. Automatic equipment represents more than half the market as manufacturers pursue high-speed, track-and-trace ready, and labor-efficient solutions.

Pharmaceutical manufacturers are the primary users, but contract manufacturing organizations (CMOs) are rapidly investing in modern equipment to address growing outsourced production. Regionally, Asia Pacific leads with over 40% share, fueled by booming local pharma production, while North America and Europe maintain strong positions due to compliance-driven demand and advanced technology adoption.

Looking for in-depth insights? Grab the full report: https://www.datamintelligence.com/buy-now-page?report=pharmaceutical-packaging-equipment-market

Regional Analysis

North America (US)

North America holds a market share of about 43.6%, anchored by stringent FDA regulations, accelerated drug approvals (55 novel drugs in 2023), and high automation adoption rates: 15% increase in robotic packaging system installations between 2022 and 2024. Demand is also driven by rising vaccine output (9% increase in 2023) and the need to securely package biologics and new cancer drugs.

Asia Pacific

Asia Pacific is the fastest-growing region, accounting for over 40% of global share. China and India are major pharmaceutical manufacturing and export hubs, benefiting from government incentives and investment. For instance, India’s PLI scheme allocated USD 2 billion in 2023, fueling demand for advanced blister and strip packaging machines. In 2023, China approved over 12,000 generic drugs—a 20% increase, driving packaging automation adoption. The region’s growth is further sustained by population needs, regulatory standards, and vaccine production surges.

Other Key Regions

• Europe: Advanced pharmaceutical output and leadership in packaging machinery exports, with Germany standing out for innovation and automation.

• Latin America, Middle East & Africa: Increasing investments in healthcare infrastructure and local pharmaceutical production, encouraging adoption of modern equipment.

Conclusion

The pharmaceutical packaging equipment market is on a trajectory of steady growth, championed by regulatory pressure, the expansion of the pharmaceutical manufacturing base, and the strategic push toward automation and sustainability. Asia Pacific’s rise as a global manufacturing center, combined with North American and European advances in high-speed, flexible, and compliant machinery, will continue to shape the industry through 2030. As drug formats diversify and serialization requirements intensify, investments in next-generation equipment and innovative materials are expected to drive efficiency, quality, and safety in pharmaceutical packaging worldwide.

Get Corporate Access to Live Pharmaceutical Packaging Equipment Industry Intelligence Database: https://www.datamintelligence.com/reports-subscription

Related Reports:

Global Molded Fiber Packaging Market reached US$ 7.6 billion in 2023 and is expected to reach US$ 9.8 billion by 2031, growing with a CAGR of 3.2% during the forecast period 2024-2031.

Contract Pharmaceutical Packaging Market Size reached US$ 15.21 billion in 2024 and is expected to reach US$ 26.59 billion by 2032, growing with a CAGR of 7.23% during the forecast period 2025-2032.

Sai Kumar

DataM Intelligence 4market Research LLP

+1 877-441-4866

sai.k@datamintelligence.com

Visit us on social media:

LinkedIn

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.